GOKISO Climber

Features

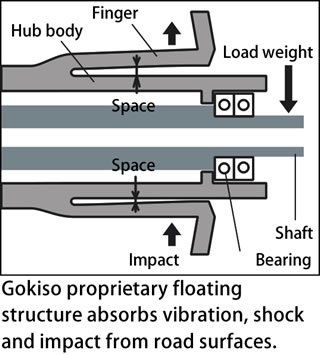

This elastic structure hub body is machined from Extra Super Duralumin "A7075T73", "GOKISO Climber Through-Axle Disc Hub" is the same design philosophy with "Climber S-Spec" and "Super Climber" which have the elastic structure is NC machined to absorb stress on the bearings from road vibration, shock and other unnecessary stress.

The hub body construction and rolling performance remain the same, but are now compatible with through axle and disc brakes.

All parts that make up the hub are machined with ultra-high precision from aluminum alloy A7075T73 and titanium alloy Ti-6Al-4V under strict quality control.

Four P5 precision grade bearings are used in the front and six in the rear.

Even the GOKISO Climber through-disk hub is designed and built as an ultra-high precision hub, with every possible attention paid to design, machining precision and assembly, all processes to maximize "rotational performance".

The hub body construction and rolling performance remain the same, but are now compatible with through axle and disc brakes.

All parts that make up the hub are machined with ultra-high precision from aluminum alloy A7075T73 and titanium alloy Ti-6Al-4V under strict quality control.

Four P5 precision grade bearings are used in the front and six in the rear.

Even the GOKISO Climber through-disk hub is designed and built as an ultra-high precision hub, with every possible attention paid to design, machining precision and assembly, all processes to maximize "rotational performance".

The Shock Absorbing Structure;

Ultra-High-precision NC machined

"one-piece" structure.

Ultra-High-precision NC machined

"one-piece" structure.

Aircraft jet engines require powerful propulsion and stable high RPM, and the bearings that support the main shafts with elastic shock absorbing structures to reduce rotational vibration and prevent damage caused by "bird strike" are widely equipped in the airliner field.

We have sought that an elastic structure is able to provide high rotational performance to bearings and hubs even for the GOKISO through-disc hub.

Especially in terms of rotational performance, high rigidity while being as lightweight as possible, and each parts to be ultra-high precision, so we choose elastic structure is the "climber structure", the hub body is machined, and choose the material "titanium alloy Ti-6Al-4V" for the shaft.

We have sought that an elastic structure is able to provide high rotational performance to bearings and hubs even for the GOKISO through-disc hub.

Especially in terms of rotational performance, high rigidity while being as lightweight as possible, and each parts to be ultra-high precision, so we choose elastic structure is the "climber structure", the hub body is machined, and choose the material "titanium alloy Ti-6Al-4V" for the shaft.

Adopt aluminium alloy

"A7075T73" on hub body,

Titanium alloy "Ti-6Al-4V" on shaft.

"A7075T73" on hub body,

Titanium alloy "Ti-6Al-4V" on shaft.

The hub body that type of "Climber" is NC machined from solid extra-super-duralumin A7075T73.

The front hub, it's composed of a cylindrical body, including 4pcs P5 grade bearings on the inside and the spoke flange, both are connected by 14 fingers on each side.

These 14-fingers: elastic structure absorb any stress even when wheels are subjected to impact and vibration from the road, and keep the bearings on the left and right sides precisely so that making the smooth rotation, and also cut off from these impacts and even distortion of body shell that could hinder their rotation.

The front hub, it's composed of a cylindrical body, including 4pcs P5 grade bearings on the inside and the spoke flange, both are connected by 14 fingers on each side.

These 14-fingers: elastic structure absorb any stress even when wheels are subjected to impact and vibration from the road, and keep the bearings on the left and right sides precisely so that making the smooth rotation, and also cut off from these impacts and even distortion of body shell that could hinder their rotation.

Ultra-high-precision machining

providing precisely and

smooth rotation performance.

providing precisely and

smooth rotation performance.

In also the rear hub body, the elastic structure; 14 fingers are machined on body shell made of solid aluminum alloy A7075T73. It can absorb any shock and vibration during high-speed riding and even cut off the warping stress caused by hard braking.

The rear hub uses a total of 6 P5 grade bearings, two each on the left and right sides for hub rotation, and two on both sides of the free hub for free body rotation. Double rows of bearings are used at each position to achieve high static and dynamic loads.

The rear hub uses a total of 6 P5 grade bearings, two each on the left and right sides for hub rotation, and two on both sides of the free hub for free body rotation. Double rows of bearings are used at each position to achieve high static and dynamic loads.

P5 grade(DIN)high-precision bearing

The "Climer" model employs P5 class precision bearing. Unlike "GOKISO" hub or "Super Climber" hub, single row bearings of larger diameter are placed on both sides of the hub. Changing double row bearing to single row bearing results in lighter weight, while maintaining load capacity by employing larger diameter bearings.

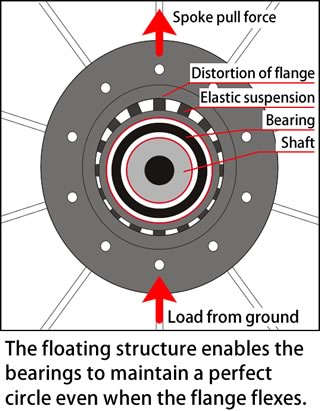

GOKISO’s shock absorbing and elastic body suspension is the ultimate solution to axle deformation.

Same as the "Super Climber" model, the "Climber" model has the elastic body suspension structure on the perimeter of the hub body to absorb the impact load from a road surface.

Moreover, since the elastic body structure floats flanges from body shell, the external input from the rim and spokes do not reach a bearing directly.

When the hub receives the external force that comes from rider’s weight, impacts, and strong torque of pedaling, its flanges change its form slightly according to stress.

However, the elastic body structure of the super climber model can continue maintaining the perfect rotation without deformation of bearings due to separated flange and body.

Moreover, since the elastic body structure floats flanges from body shell, the external input from the rim and spokes do not reach a bearing directly.

When the hub receives the external force that comes from rider’s weight, impacts, and strong torque of pedaling, its flanges change its form slightly according to stress.

However, the elastic body structure of the super climber model can continue maintaining the perfect rotation without deformation of bearings due to separated flange and body.

Spherical nut and washer

A hub shaft could get deformed during wheel installation when clamping the wheel to the folk or the frame using a quick lever.

Our spherical nut and washer are the successful solution for these problems. By keeping the hub shaft straight regardless of frame deformation, we have achieved the highest rotation accuracy without abrading or damaging the bearing.

Our spherical nut and washer are the successful solution for these problems. By keeping the hub shaft straight regardless of frame deformation, we have achieved the highest rotation accuracy without abrading or damaging the bearing.

Color

Matte Red

Matte Black

Specification

| Front Hub | Rear Hub | |||

|---|---|---|---|---|

| Freehub body | - | Campagnolo 11/12s | Shimano 11/12s | SRAM XDR 12s |

| O.L.D. | 100mm | 142mm | ||

| Spoke Holes | 24H ~ 36H | 24H ~ 36H | ||

| Center to flange * | 22.1mm / 28.6mm | 33.6mm / 18.1mm | ||

| P.C.D. * | φ60mm / φ55mm | φ60mm / φ60mm | ||

| * | mm / mm = left / right | |||

| Recommended spoke | SAPIM CX-RAY | |||

| Ratchet | - | 4 Pawls / 92 notch | ||

| Skewer diameter | φ12mm | φ12mm | ||

| Weight | 260g | 460g | ||

| Bearing PCS | 4 pcs | 8 pcs | ||

| Bearing | Stainless Non-contact sealed deep groove bearing (DIN P5) | |||

| Material : Hub body / Shaft | A7075T73 / Ti6Al4V | |||